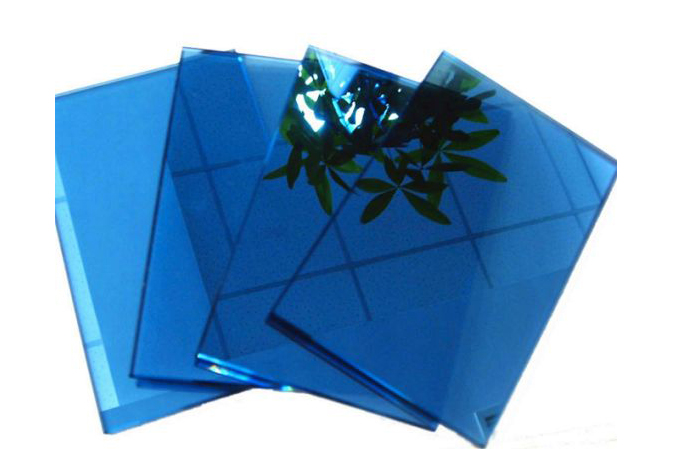

Factory For Custom Made Sound Proof Anti-Ultraviolet Clear/Tinted/Reflective/Tempered/Low E Insulated Glass products

All we do is often involved with our tenet ” Purchaser to start with, Rely on initially, devoting over the food stuff packaging and environmental defense for Factory For Custom Made Sound Proof Anti-Ultraviolet Clear/Tinted/Reflective/Tempered/Low E Insulated Glass products, Our business eagerly looks ahead to creating long-term and pleasant business partner associations with customers and businessmen from everywhere in the world.

All we do is often involved with our tenet ” Purchaser to start with, Rely on initially, devoting over the food stuff packaging and environmental defense for China Double Glazing Glass and Insulated Glass, Due to good quality and reasonable prices, our products and solutions have been exported to more than 10 countries and regions. We’re looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

Product Description

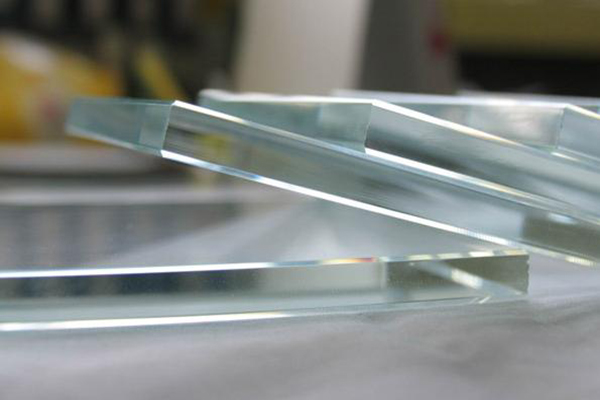

Ultra Clear Glass has its own unique advantages

1. The self-detonation rate of glass is low

Because the raw materials of ultra-white glass generally contain less impurities such as NiS, the fine control in the process of raw material melting makes Ultra Clear Glass have more uniform composition than ordinary glass, and its internal impurities are less, which greatly reduces the possibility of self-explosion after tempering, and the safety factor is higher.

2. Color consistency

Because the iron content in the raw material is only 1/10 or less than that of ordinary glass, Ultra Clear Glass absorbs less of the green and purple bands of visible light than ordinary glass, ensuring the consistency of the glass color. At the same time, because of the low UV transmittance, relatively can reduce the damage of UV to indoor furniture and articles, play a good protective effect.

3. High transmittance and good permeability of visible light

Ultra Clear Glass relative to ordinary glass in visible light of red and purple band absorption less visible light transmittance is high, good permeability, 6mm thickness of glass is greater than 91% visible light transmittance, with crystal clear crystal quality, make the display more clear, more can highlight the exhibits of the real appearance, used in building materials, can also make the indoor environment better.

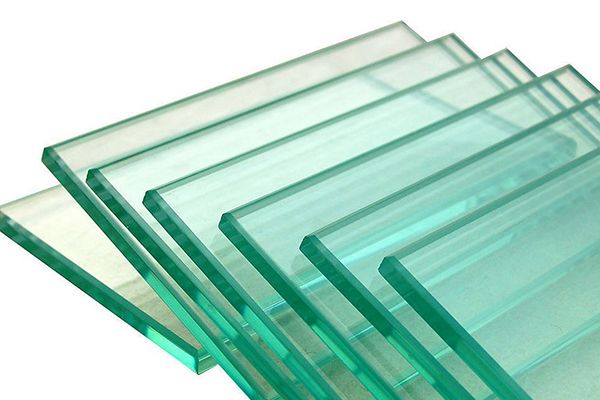

Product Applications

Because the technical barrier of Ultra Clear Glass is relatively high, it has a high added value, and the excellent product characteristics of Ultra Clear Glass also make Ultra Clear Glass more favored by the high-end market, such as the interior and exterior decoration of high-grade buildings, high-grade horticultural buildings, high-grade glass furniture, various imitation crystal products and cultural relics protection display, high-grade gold jewelry display, etc. High-end shopping malls, shopping center space, brand stores and so on.

In China, the application of Ultra Clear Glass is rapidly expanding, such as Beijing National Center for the Performing Arts, Beijing Botanical Garden, Shanghai Opera House, Shanghai Pudong Airport, Hong Kong Convention and Exhibition Center, Nanjing Chinese Arts Center and other hundreds of projects have been used Ultra Clear Glass. At the same time, Ultra Clear Glass is also used in some scientific and technological products, electronic products, high-grade car glass, solar cells and other industries because of its good transmittance. The development and application of solar energy will also provide huge business opportunities for the development of Ultra Clear Glass.Tempered glass production is a multi-step process carried out in a factory setting. Here are the general steps involved in the production of factory tempered glass:

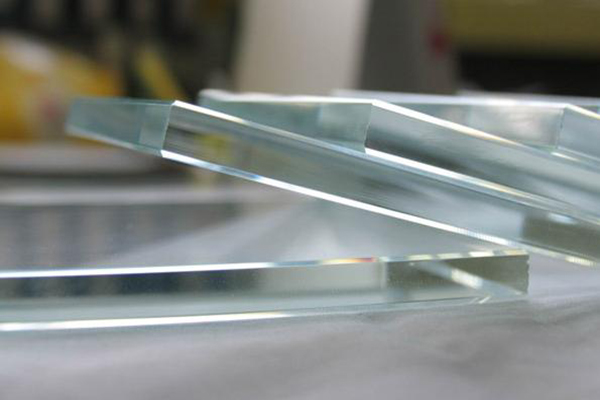

1. Glass cutting: First, large sheets of glass are cut into smaller pieces according to the desired dimensions.

2. Glass cleaning: Then, the glass pieces are thoroughly cleaned and dried to remove any dirt or debris.

3. Glass heating: Next, the glass is heated to a temperature of around 600-700°C in a special furnace, known as a tempering oven.

4. Quenching: After the glass is heated, it is rapidly cooled by blasting cold air onto both sides of the glass surface, which makes the outer layers contract and compress, while the inner layers expand. This creates a balance of tension and compression that gives tempered glass its unique strength.

5. Quality control: Finally, the tempered glass is inspected for any defects or imperfections, and if there are no issues, it is ready for packaging and shipment.

The production of tempered glass undergoes a rigorous testing process to ensure that it meets the necessary safety standards and can withstand high impact.