We all know that advanced production equipment can greatly improve production efficiency.Recently, our company has entered into cooperation with Glaston, a glass processing equipment supplier in Finland. Glaston has decades of research and development experience, advanced technology and equipment. Before soldiers and horses move, grain and grass go first. With advanced machinery and equipment, there is no need to worry about the production efficiency and product quality behind.

Glaston is an industry company dedicated to providing heat-treated glass manufacturing technology and services to most countries. The equipment is used to manufacture high quality glass for buildings, solar energy, appliances and automobiles. In addition to excellent product quality, their equipment is known for superior reliability, stable operation and energy saving. Integration of technology with specific use of support and services. They continue to innovate and develop so that glass processing enterprises can achieve higher standards in quality and safety.

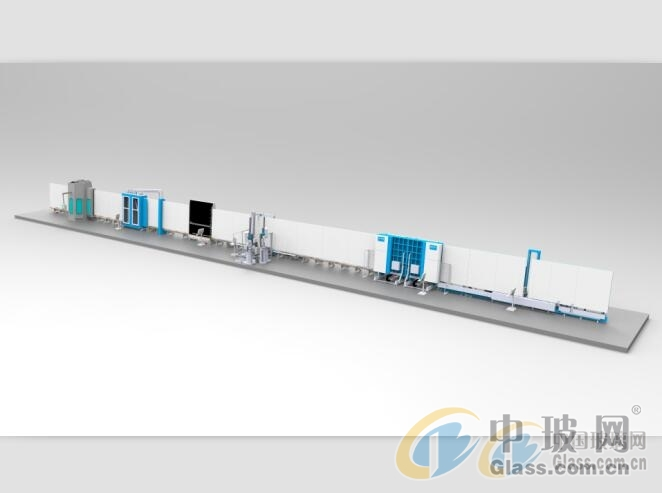

This time, our company purchased two product lines, Insulating glass production line and Plate glass tempering furnace production line

1.The Insulating glass production line,largest glass size of the hollow line can be processed is 2700*6000, which can be inflated and three pieces of glass of different sizes can also be processed together; Achieve revolutionary sandwich technology for all glass types Low-E and the preferred choice of printed glass flexible laminate all glass sizes parametrless processing and flexible laminating. Save energy, resources and costs up to 50% energy saving process control is very simple uniform heating reduces waste by half.

2. Plate glass tempering furnace production line that can be accommodated in the tempering furnace is 3300*6000, and all the original glass pieces of 4mm can be tempered.The equipment can temper all types of glass flexible processing of a variety of glass sizes both energy saving and improve quality. With stable high quality and high yield, iControL can easily control the processing process without large on-chip delay and minimize rework.

Toughening furnace production line can accommodate the glass size increase can meet the needs of more customers, the stable operation of equipment, stable, reliable can achieve one-stop production, production workshop can realize unmanned operation to save labor costs, reduce production costs, but also reduce the price to bring real benefits to consumers. The sustainable operation of production facilities reduces defective products.

The arrival of the new machine has injected a new force into the production workshop of our factory, leading our glass deep processing industry to a higher peak. With the help of the new equipment, we are going to create more excellent products and ensure the delivery rate. In the future, we are dedicated to provide our customers with quality products and intimate service.

The two sides reached a deal and shook hands

Architectural Glass Manufacturer directly for Low Emissivity Glass, Tempered glass, Hollow glass, Laminated glass etc. if you are interested in buying or business, pleaease do not hesitate to contact below officially:

● Nansha Industrial Zone, Danzao Town, Nanhai District, Foshan City, Guangdong Province,China

● Tel:+86 757 8660 0666

● Fax:+86 757 8660 0611

Post time: Apr-11-2023