The use of insulating glass in the field of construction more and more scenes, with the increase in use, different manufacturing processes and selection of materials have also appeared a lot of development and change, then how should we choose?

The middle layer of insulating glass generally chooses the best width of 9A-15A, A refers to mm; The energy-saving effect of the insulating glass air layer within this spacing is the best, if it is too large or smaller than this value, it will reduce the insulation of the insulating glass and reduce the K value of the insulating glass. In other words, the width of the insulating glass aluminum partition is recommended to be between 9mm-15mm.

Insulating glass spacers are available in different materials, colors and thicknesses. For insulating glass devices, the above three points are essential and will affect the performance. At the same time, the material determines the amount of heat and cold that can pass through the glass and, therefore, plays a large role in the energy efficiency of the device.

In terms of materials, spacers are usually divided into two main groups – aluminum sheets or warm edges, etc.

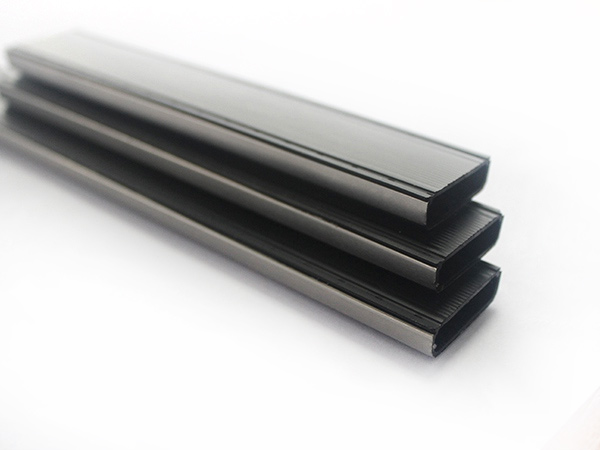

Aluminum spacer strip

Initially, aluminum spacer bars were the most widely used type of spacer bars, which could provide a basic level of performance. Aluminum is a structurally strong material that is a very efficient conductor of heat. This means that aluminum spacers make it easy for indoor heat to escape from the outside. What’s more, the cold glass edges caused by aluminum create a temperature difference between the center of the glass and its edges. Therefore, this insulating glass device is easy to condense.

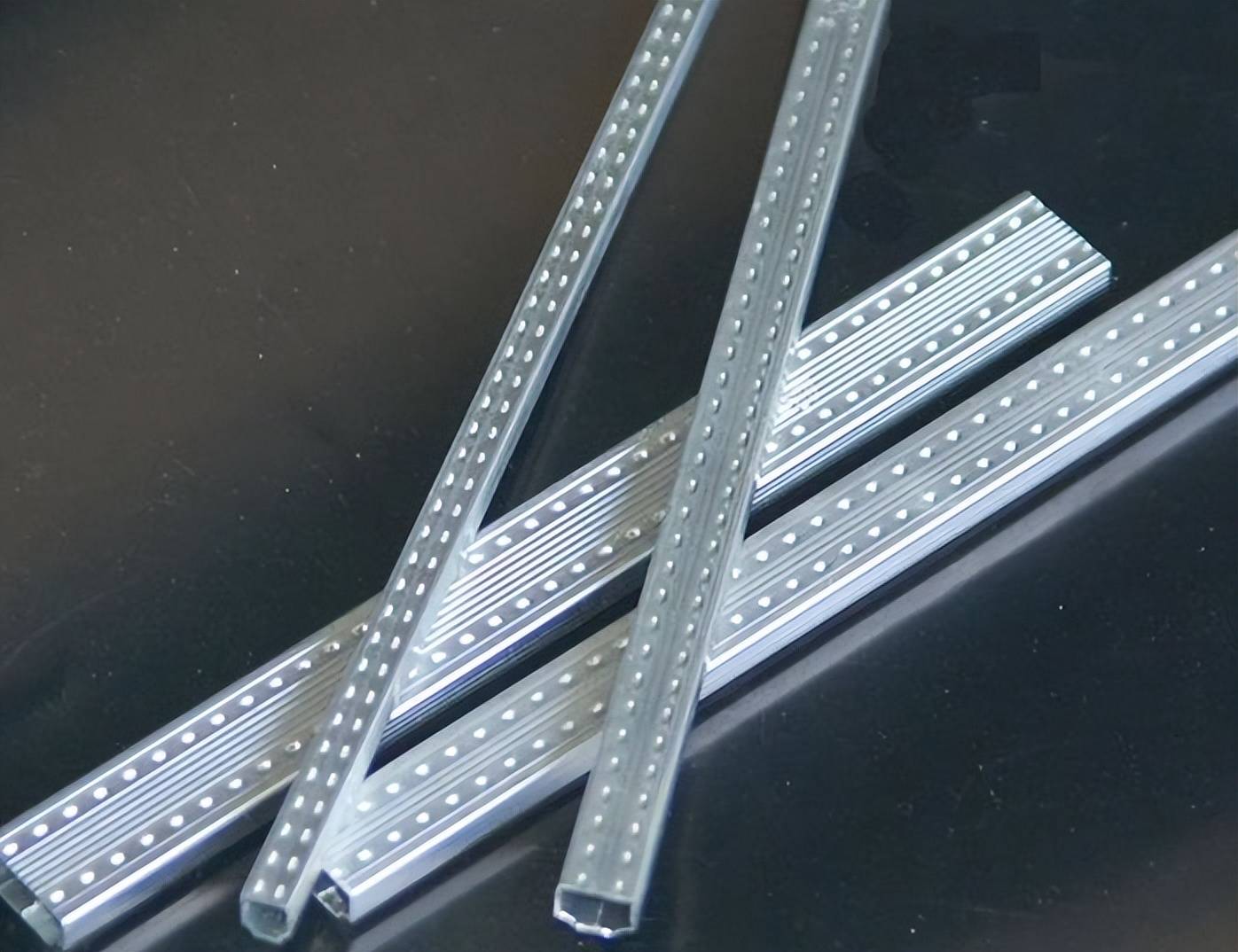

Warm edge spacer

However, the growing demand for energy has created a need for new solutions. Therefore, warm edge spacers made of low-conductivity materials are used as a high-performance alternative to traditional aluminum spacers. Warm edge technology has fundamentally changed the window manufacturing market. This technology not only helps prevent heat loss through the Windows and increases the energy efficiency of the unit, but also reduces condensation problems.

Stainless steel warm edge spacer

Stainless steel material and its properties are similar to aluminum spacers. However, stainless steel has only one-tenth the thermal conductivity of aluminum, and its condensing ability is also improved. Nevertheless, the electrical conductivity of stainless steel spacers is several times higher than that of other warm spacers.

Plastic-metal mixed warm edge spacer strip

This type of warm edge spacer is usually made of plastic, such as polycarbonate, polypropylene, etc., and is combined with low metal spacers.

Flexible warm edge spacer

The flexible spacer is made of flexible thermoplastic or silica-based material with molecular sieve. Among them, the hot melt butyl type spacer bar without any additives is the most prominent. The modern insulating glass spacer market is indeed very complex and diverse, so it is impossible to cover all aspects in a short blog.

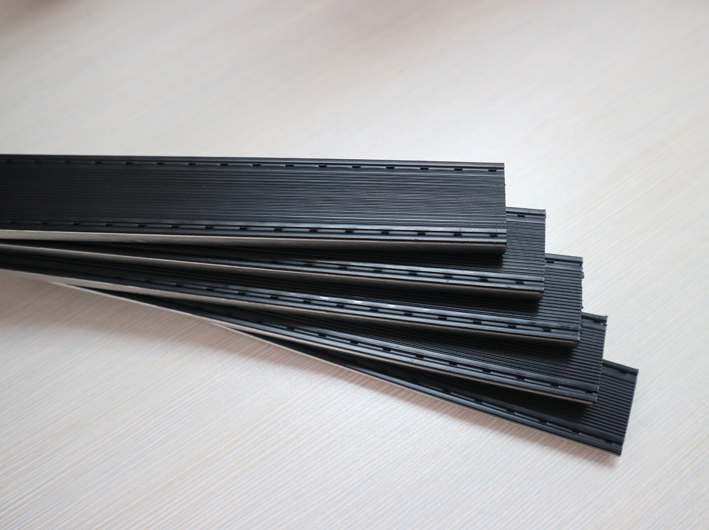

The selection standard of hollow aluminum spacer

First, look. Good surface gloss, no obvious oil stains. Because there is too much oil, butyl glue will not be good, thus affecting the quality and production of insulating glass, air tightness will be greatly reduced, and the service life of insulating glass will be shortened. Generally, when cutting the interval bar, it is found that there is too much oil, and it must be wiped with alcohol until the oil is completely removed, or it can be used with white wine.

Second, look at the thickness of the septum. That’s what we call wall thickness. Generally speaking, the wall thickness of the aluminum strip is calculated by a few points, and it is difficult for professional personnel to determine the actual thickness of the selected aluminum strip. The method of weighing without packaging can be used. Because each specification of hollow aluminum partition, each wall thickness, per kilogram of the output of the product is standard, and the error is not large.

Third, about the accessories used in the hollow aluminum spacer. For example, the purchase of molecular sieve (thousand drying agent). The simplest detection method is to put some molecular sieve in the hand and then sprinkle a little water, feel the temperature of the molecular sieve, the faster the temperature rises, the higher, the better, to prove that the moisture absorption effect of this molecular sieve is still good.

Address: NO.3,613Road,Nansha Industrial Estate, Danzao Town Nanhai District, Foshan City, Guangdong Province,China

Website: https://www.agsitech.com/

Tel: +86 757 8660 0666

Fax: +86 757 8660 0611

Mailbox: info@agsitech.com

Post time: Aug-04-2023